Form-in-Place

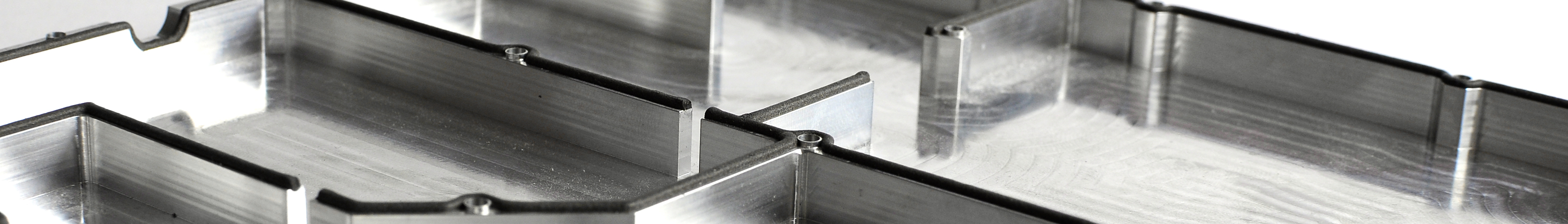

Automated technology that dispenses Form-in-Place conductive elastomer gaskets on metal or plastic housings. The system applies programmed gasket beads with pinpoint accuracy in four axes. This allows for compensation for uneven surfaces in castings and molded parts and provides consistent highly reliable seals.Gaskets can be applied on flanges as narrow as 0.50 mm, affording more space for board components or allowing smaller overall packaging.

Dispensed Gasketing Selection Guide

EMI Shielding Gasket

| Typical Properties | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Part no. | F5301 | F5304 | F5305 | F5314 | F5321 | F5221 | F5521 | F5381 | F5382 |

| Elastomer Binder | Silicone Rubber | Silicone Rubber | Silicone Rubber | Silicone Rubber | Silicone Rubber | Silicone Rubber | Silicone Rubber | Fluorosilicone | Fluorosilicone |

| Conductive Filler | Ni/Gr | Ni/Gr | Ni/Gr | Ni/Gr | Ni/Gr | Ag/Cu | Ag/AI | Ni/Gr | Ni/Gr |

| Curing System | Thermal | Thermal | Thermal | Thermal | Moisture | Moisture | Moisture | Thermal | Thermal |

| Hardness (Shore A) | 75 | 30 | 40 | 35 | 70 | 40 | 55 | 60 | 75 |

| Adhesion on Al plate (N/cm^2) | >100 | >80 | >80 | >80 | >80 | >80 | >80 | >80 | >80 |

| Compression Set 72hrs @70oC | 30% | 25% | 30% | 25% | 25% | 30% | 25% | 25% | 25% |

| Operating Temp. Range (oC) | -45-150 | -45~150 | -45~150 | -45~150 | -45~150 | -45~150 | -45~150 | -55~150 | -55~150 |

| Max. Intermittent Using Temp. (oC) | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 | 200 |

| UL Flammability Rating | 94V-0 | 94V-0 | 94V-0 | 94V-0 | 94V-0 | 94V-0 | 94V-0 | 94V-0 | 94V-0 |

| DC Throught Resistance at 30% compression, 1mm Height (Ohm) | 0.05 | 0.08 | 0.08 | 0.10 | 0.09 | 0.05 | 0.07 | 0.15 | 0.06 |

| Volume Resistivity (Ohm-cm) | 0.030 | 0.020 | 0.015 | 0.02 | 0.025 | 0.005 | 0.007 | 0.030 | 0.020 |

| Shielding Effectiveness (200MHz~10GHz) | >100dB | >100dB | >100dB | >100dB | >100dB | >100dB | >100dB | >100dB | >100dB |

| Features | Small bead application with superior adhesion | Ultrasoft, Low compression force application | Designed for applications where greater than 50% compression is required | Soft,reboundable, low compression force application for highter frequencies | Preferred material for metalized plastics, RTV version of F5301 | Superior conductivity with higher compresssion capabilities | High corrosion resistance in harshest environments | Resistance to polar solvents, fuels, oil additives, chemicals, and salt spray/fog with low outgassing | Resistance to polar solvents, fuels, oil additives, chemicals, and salt spray/fog with low outgassing |

BACK to Dispensed Gasketing Selection Guide

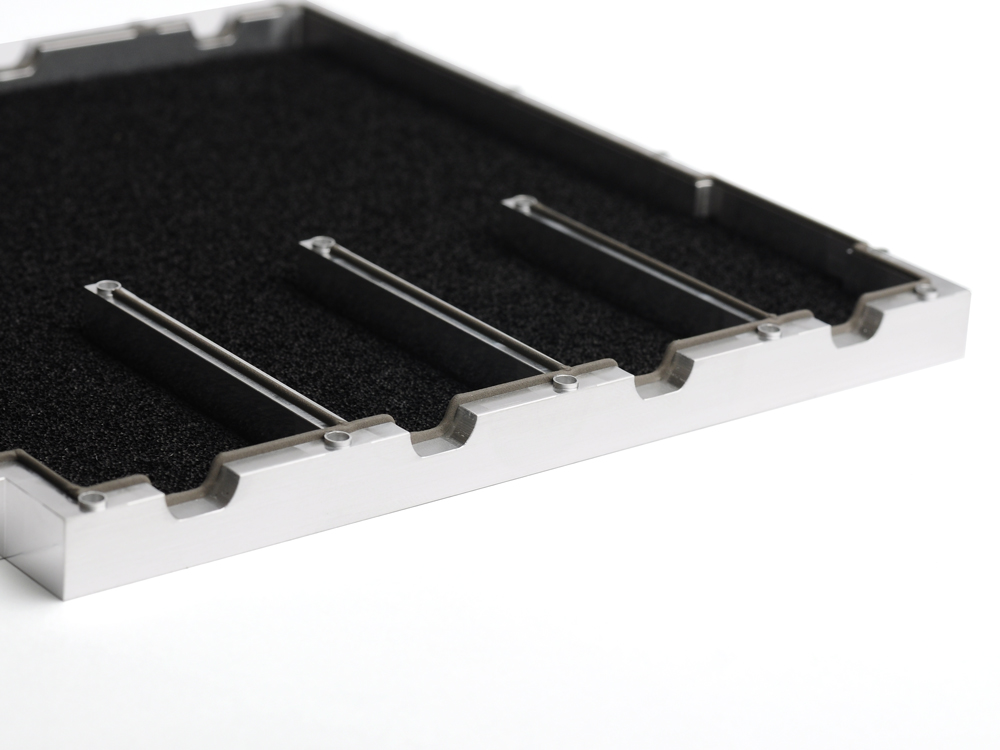

Dual-Functional Gasket

| Typical Properties | |

|---|---|

| Part Number | F9304 |

| Elastomer Binder | Silicone |

| Conductive Filler | Ni/Gr |

| Curing System | Thermal |

| Hardness (Shore A) | 35 |

| Adhesion on Al plate (N/cm 2 ) | >80 |

| Compression Set 72hrs @70 o C | 25 |

| Operating Temp. Range ( o C) | -45~150 |

| Max. Intermittent Using Temp. ( o C) | 200 |

| UL Flammability Rating | 94V-0 |

| DC Throught Resistance at 30% compression, 1mm Height (Ohm) | 0.06 |

| Volume Resistivity (Ohm-cm) | 0.020 |

| Shielding Effectiveness (200MHz~10GHz) | >100dB |

| Recommended Bead Height | |

| Features | Excellent EMI shielding performance with superior environmental sealing property |

BACK to Dispensed Gasketing Selection Guide

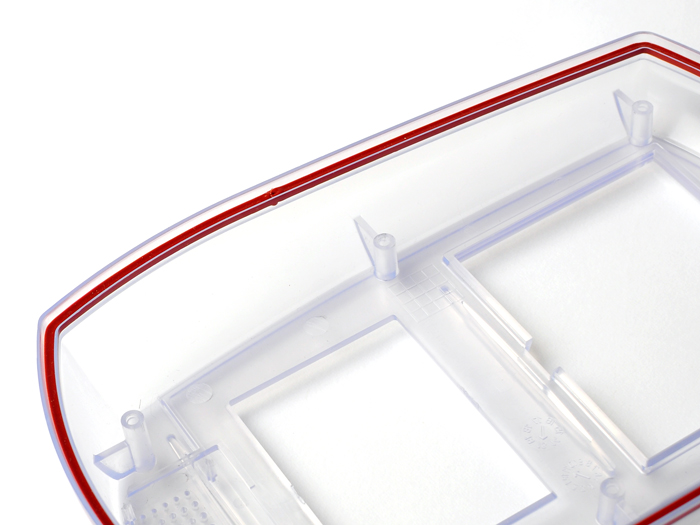

Environmental Sealing Gasket

| Typical Properties | |||||

|---|---|---|---|---|---|

| Part no. | F6003 | F6023 | F6031 | F6012 | F6081 |

| Elastomer Binder | Silicone Rubber | Silicone Rubber | Silicone Rubber | Silicone Rubber | Fluorosilicone |

| Conductive Filler | None | None | None | None | None |

| Curing System | Thermal | Moisture | Moisture | Thermal | Thermal |

| Hardness (Shore A) | 40 | 25 | 20 | 20 | 40 |

| Adhesion on Al plate (N/cm2) | >100 | >50 | >70 | >45 | >50 |

| Compression Set 72hrs @70oC | 15% | 15% | 30% | 30% | 15% |

| Elongation | 200% | 300% | 44% | 200% | 390% |

| Tear Strength (lbf/in) | 100 | 100 | >50 | >12 | >50 |

| Operating Temp. Range (oC) | -45~150 | -45~150 | -45~150 | -45~150 | -50~150 |

| Max. Intermittent Using Temp. (oC) | 200 | 200 | 200 | 200 | 200 |

| UL Flammability Rating | 94V-0 | 94V-0 | 94V-0 | 94V-0 | 94V-0 |

| DC Throught Resistance at 30% compression, 1mm Height (Ohm) | None | None | None | None | None |

| Volume Resistivity (Ohm-cm) | 1X10^12 | 1X10^14 | 1X10^14 | 1X10^15 | 1X10^14 |

| Shielding Effectiveness (200MHz~10GHz) | None | None | None | None | None |

| Recommended Bead Height | |||||

| Features | UV resistant | Ideal for weather resistant application | RTV version of F6012 with low compression force | A foam based material that is highly compressable | Resistance to polar solvents, fuels, chemicals, and salt spray/fog with low outgassion |

BACK to Dispensed Gasketing Selection Guide