Molded and Overmolding

MIP is a two component, heat curable Silicone system, optimized for Overmolding or Mold-In-Place processes.

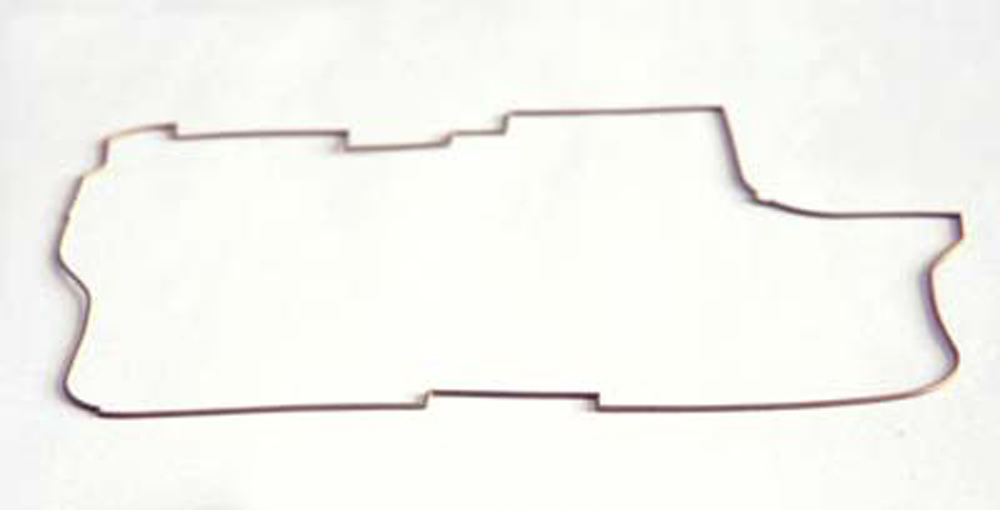

Molded Gasket

The M-1301 is designed to replace high cost silver plated particles at a fraction of the cost. The nature of the nickel plated graphite particles provides exceptional electrical conductivity and absorption properties.

Features:

- High EMI shielding effectiveness

- Flexible to fit the mechanical structure in limited space

- Addition type silicone provides good electrical stability without bleeding or migration

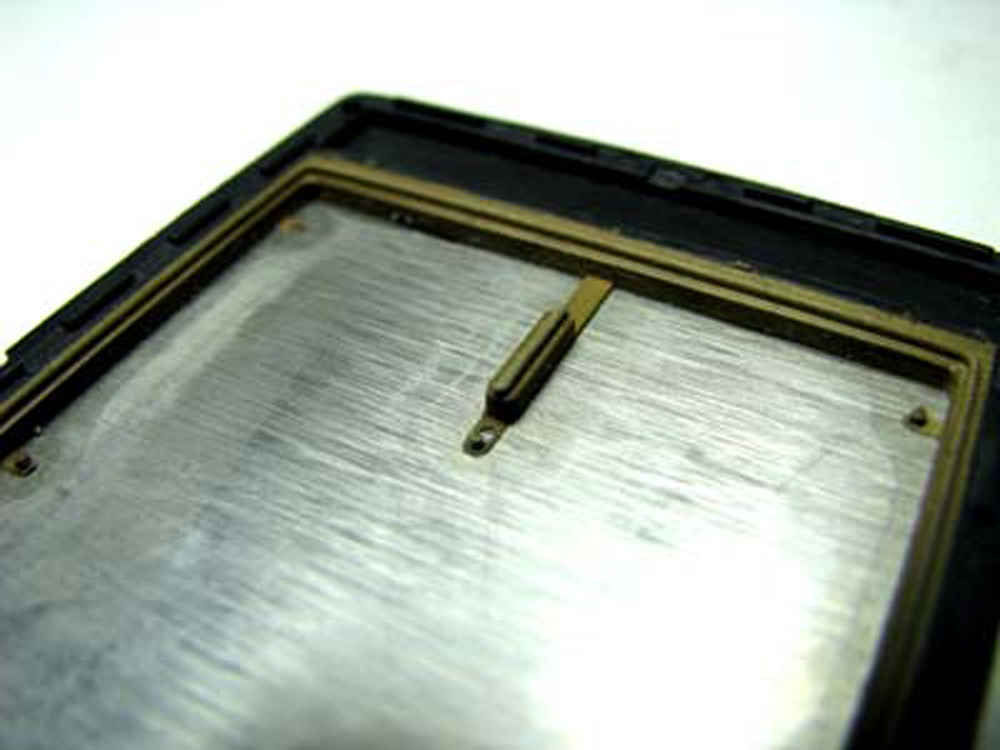

Overmolded Gasket | Mold-in-Place

Mold-in-Place (MIP) is a two component, heat curable Silicone system, optimized for Overmolding and Mold-In-Place processes. The materials highly electrical conductive and soft properties make it an excellent gasket for low pressure force applications with EMI Shielding or environmental protection needs and can be designed in various geometries.

Features:

- Soft Ag/Glass filled silicone

- High integration within mechanical structure

- Effective space utilization

- High EMI shielding effectiveness

- Addition type silicone provides good electrical stability without bleeding or migration

Extrusion

The Extruded Gasket family is formulated by Ni/Gr in highly elastic silicone rubber.

Extrusion Gasket

The Extruded Gasket family is formulated by Ni/Gr in highly elastic silicone rubber. It is designed for Electromagnetic Shielding and Environmental Seal applications with lower cost and higher contaminated resistance strengths.

Features:

- Soft Ag/Cu silicone

- High EMI shielding effectiveness

- Addition type silicone provides good electrical stability without bleeding or migration

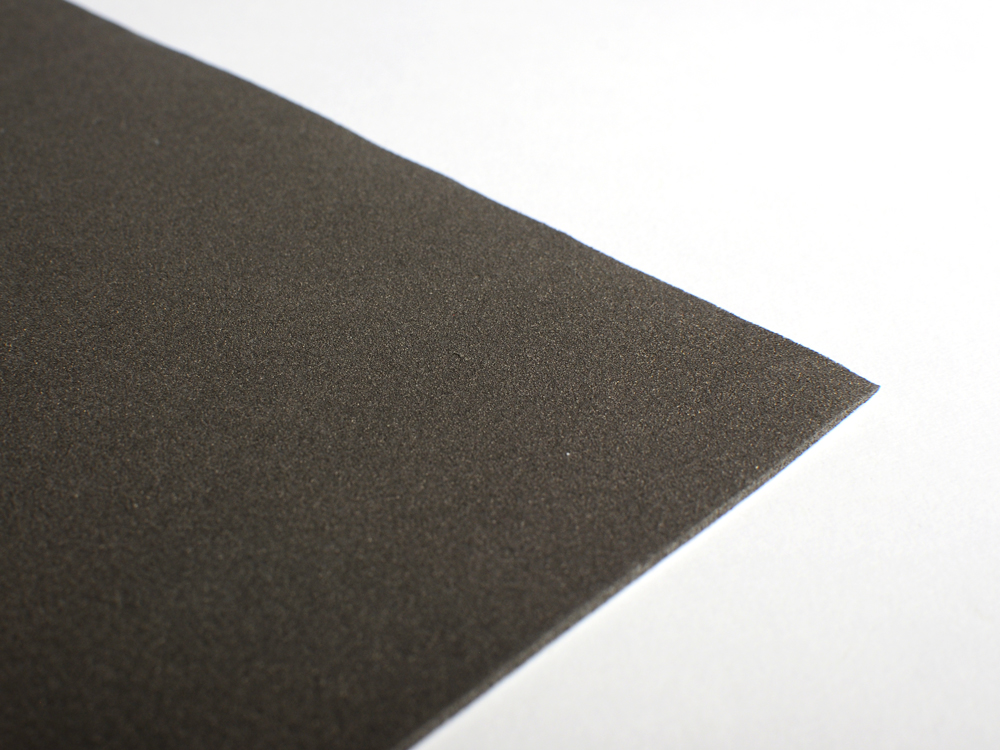

Conductive Silicone Sheet

Data Sheets