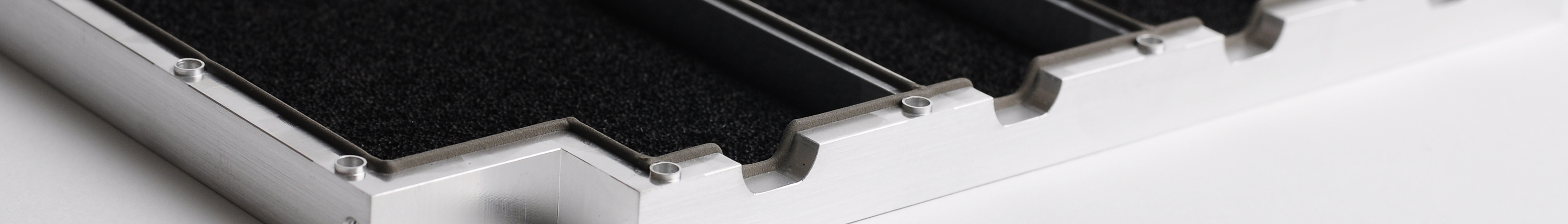

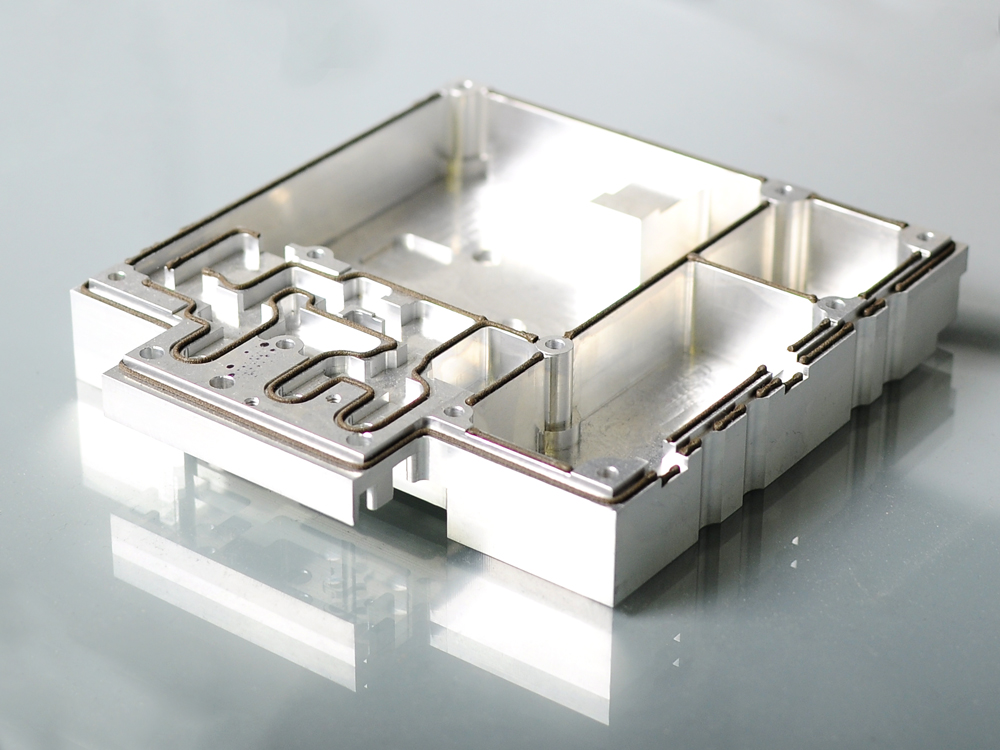

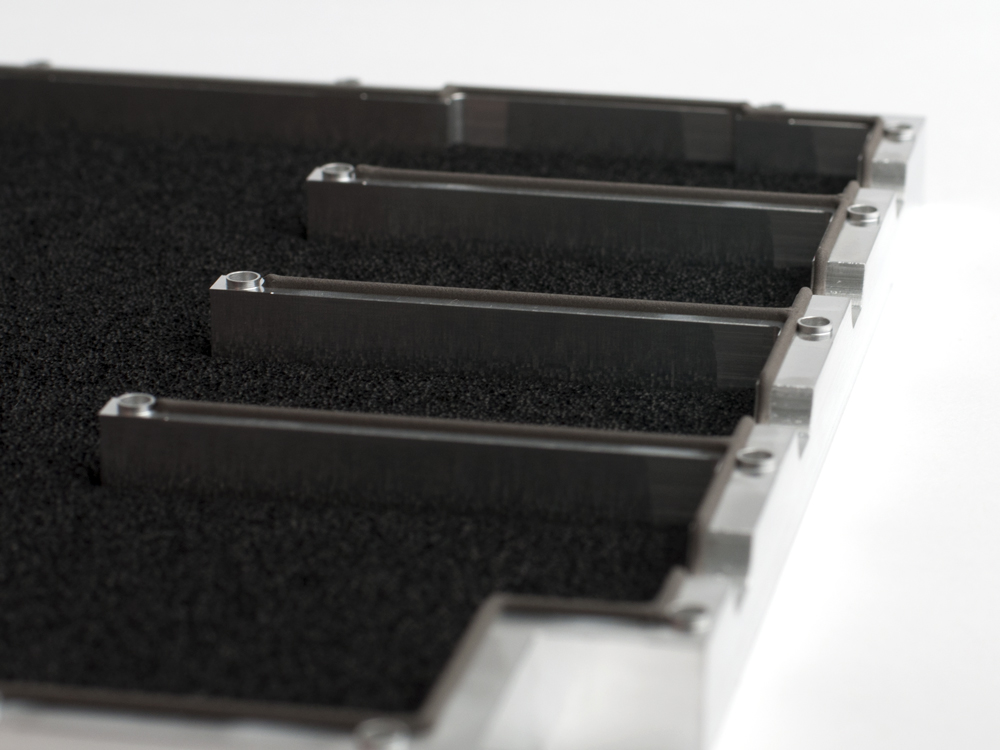

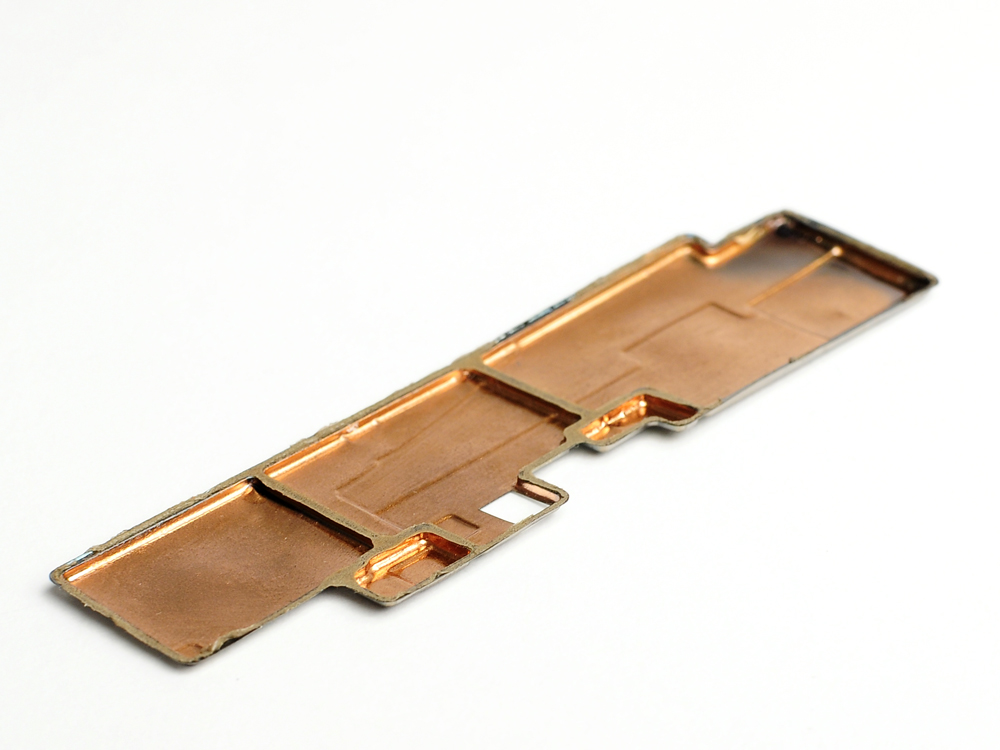

Clamshell Gasket

The Clamshell Gasket consists of an aluminum cover with a dispensed conductive silicone (Form-In-Place Gasket) on the edges. This eliminates the potential of RF leakage from substrate deformation and minimizes the number of screws required to maintain full contact with the PCB.

Benefits

- Applicable for both low and high volume applications

- Metal frame can be used to dissipate heat

- Increased board space due to thin wall requirement

Silicone additives available

- Ag/Ni

- Ag/Cu

- Ni/Graphite

Aluminum housing options

- Machined

- Extruded

- Die Cast

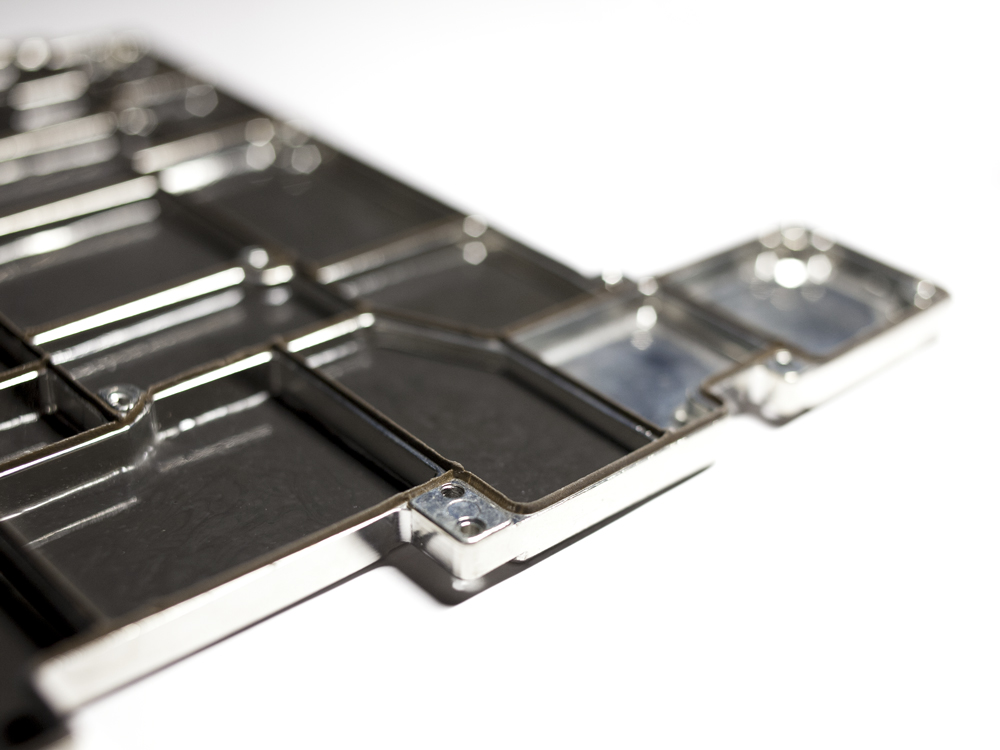

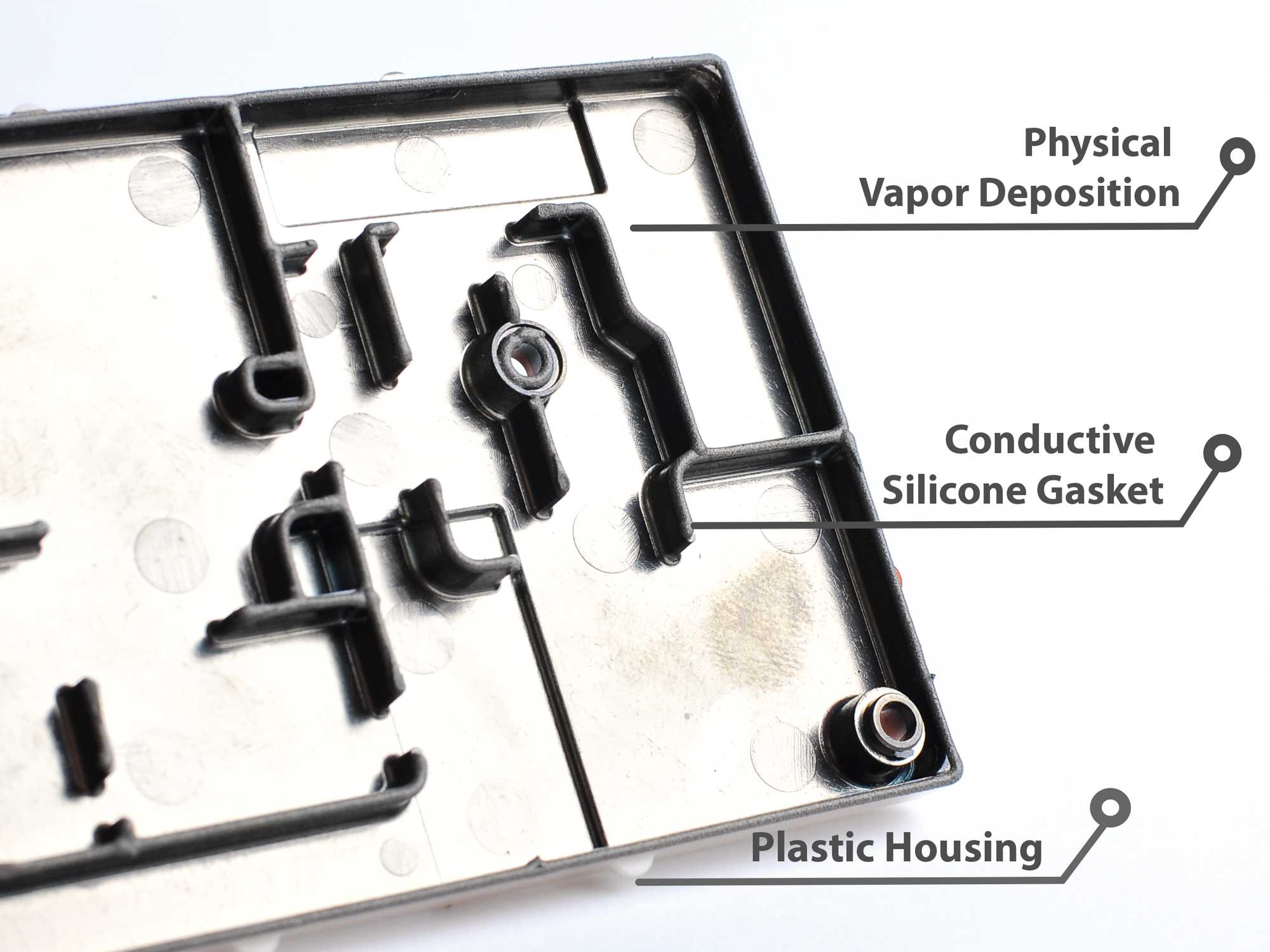

Plastic Shield Can | PCan

Pcan uses a molded plastic frame metallized with our proprietary Physical Vapor Deposition process with a conductive silicone edge to eliminate any potential gaps. Pcans are most commonly attached via screws and are an excellent solution for low cost multi-cavity applications.

Plastic Metallization (Physical Vapor Deposition)

- Various metal coating combinations available (Copper / Nichrome coating is standard)

- Excellent adhesion and conformity

- Maximum temperature 70 – 150°C

- ABS, PC, PC/ABS, PA, PPA, PPS

- Use of Glass or Carbon Fillers to adjust rigidity available

- Physical Vapor Deposition Metallization

- Robotic placement for repeatability

- Highly conductive for superior shielding

- Minimum contact width of 0.3mm

- Grounds to PCB

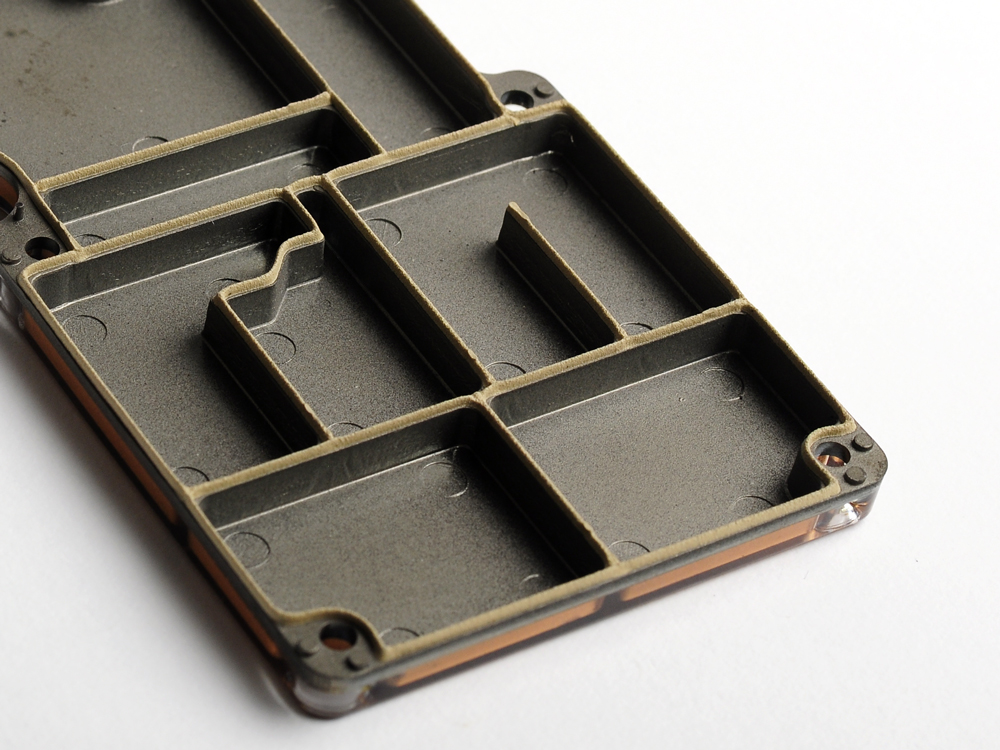

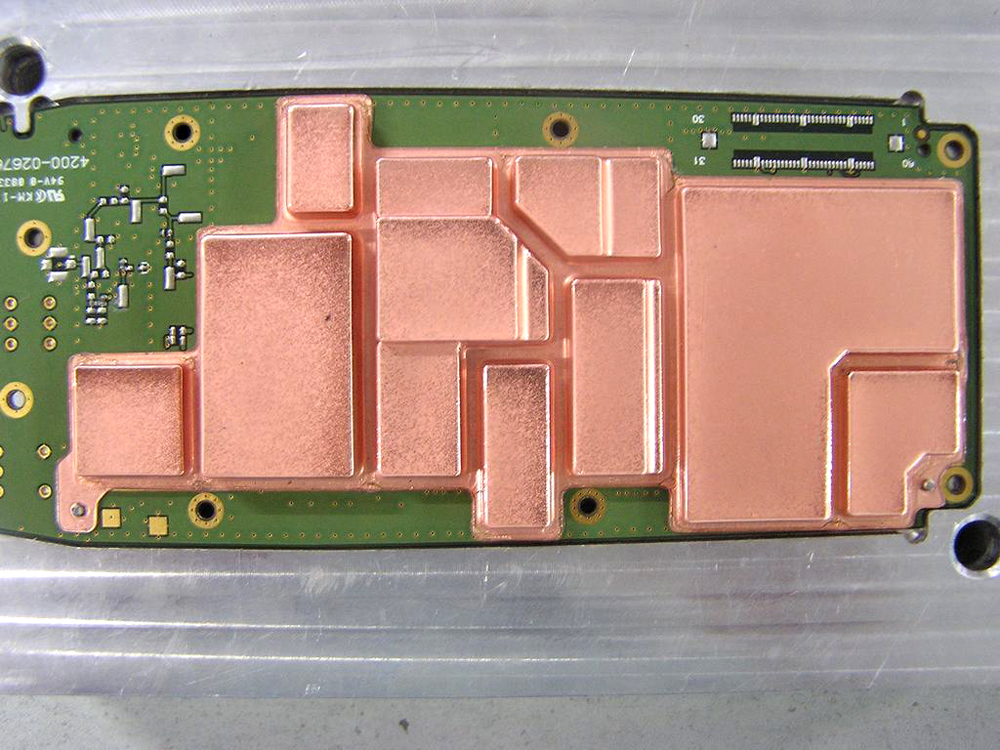

Pressure Formed Plastic Can | PFCan

A thermal formed metallized plastic film, the PFCan is perfect for low cost multi-cavity applications which require an extremely compact form factor. The gasket is typically attached after final testing via a press and can easily be removed for rework.

Benefits

- Layout design flexibility

- Ability to have multiple cavities

- Total height between 0.2mm to 20mm

- Avoid solder temperature exposure

- Easy to install and rework

- Cost effective

- Smaller footprint for space-constrained designs

- Light weight